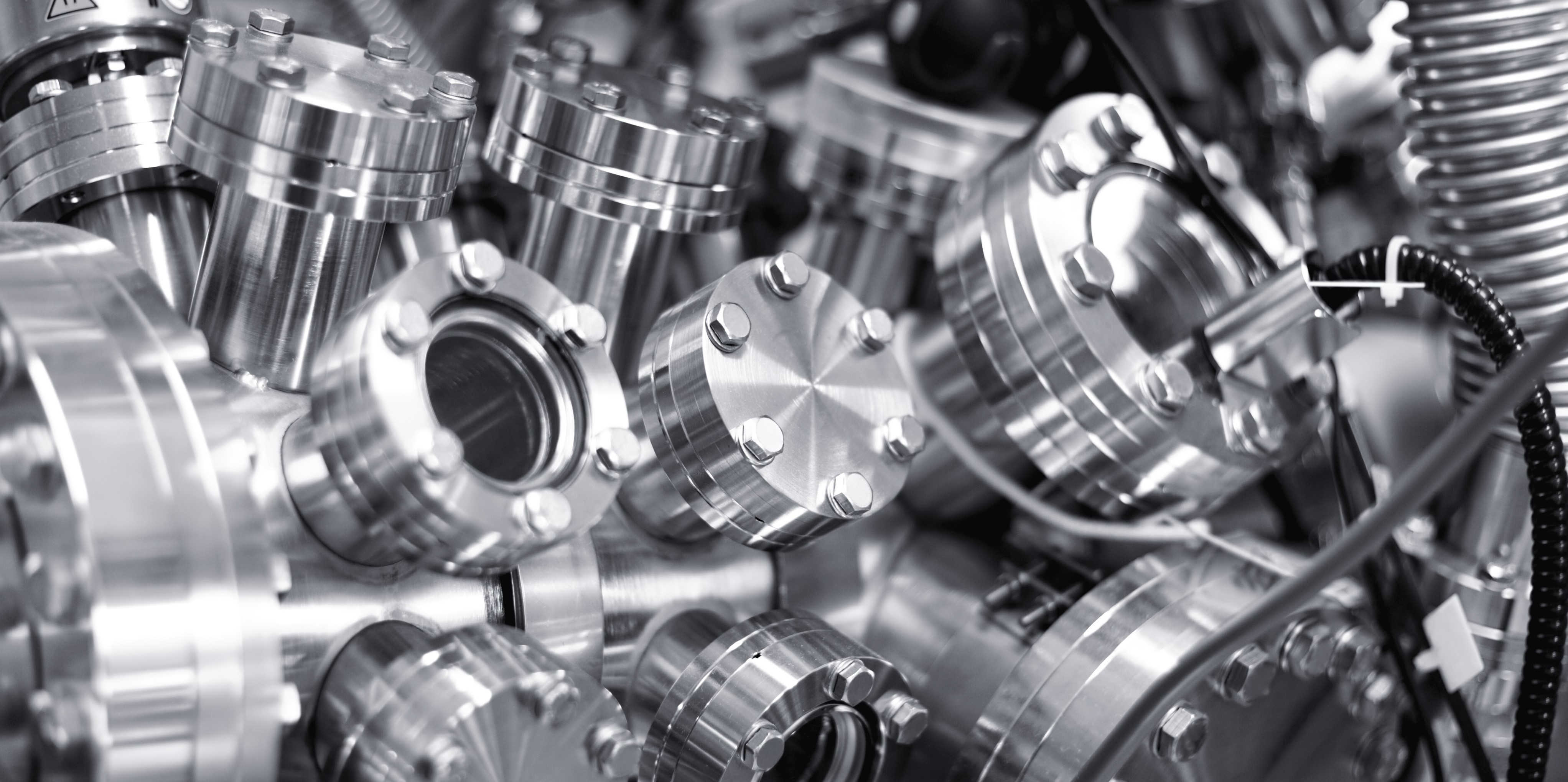

Which of our material testing methods is most effective for solving your problem will be defined in advance in a personal discussion with you. Our quotations are individually tailored to your specific problem. Our reports provide not only pure measured values but often also concrete indications of possible causes of e.g. contamination, damage or material failure.

We have a variety of methods of material testing and material analysis at our facilities, e.g.: Photo-Electron Spectroscopy (XPS, ESCA), Infrared Spectroscopy (FT-IR), Scanning Electron Microscopy (SEM) and Light Microscopy, Atomic Absorption Spectroscopy (AAS), Profilometry and many more.

If you wish, you can also look over the shoulder of our staff during the material testing of your sample and thus interactively intervene in the processing. Many questions can be answered extremely efficiently and quickly in this way.

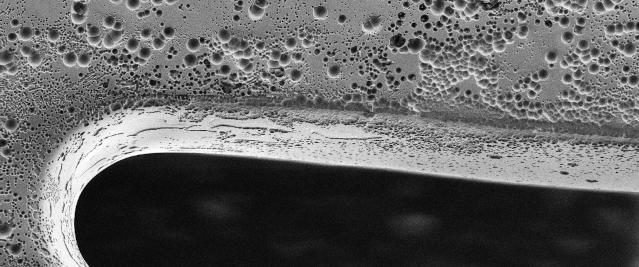

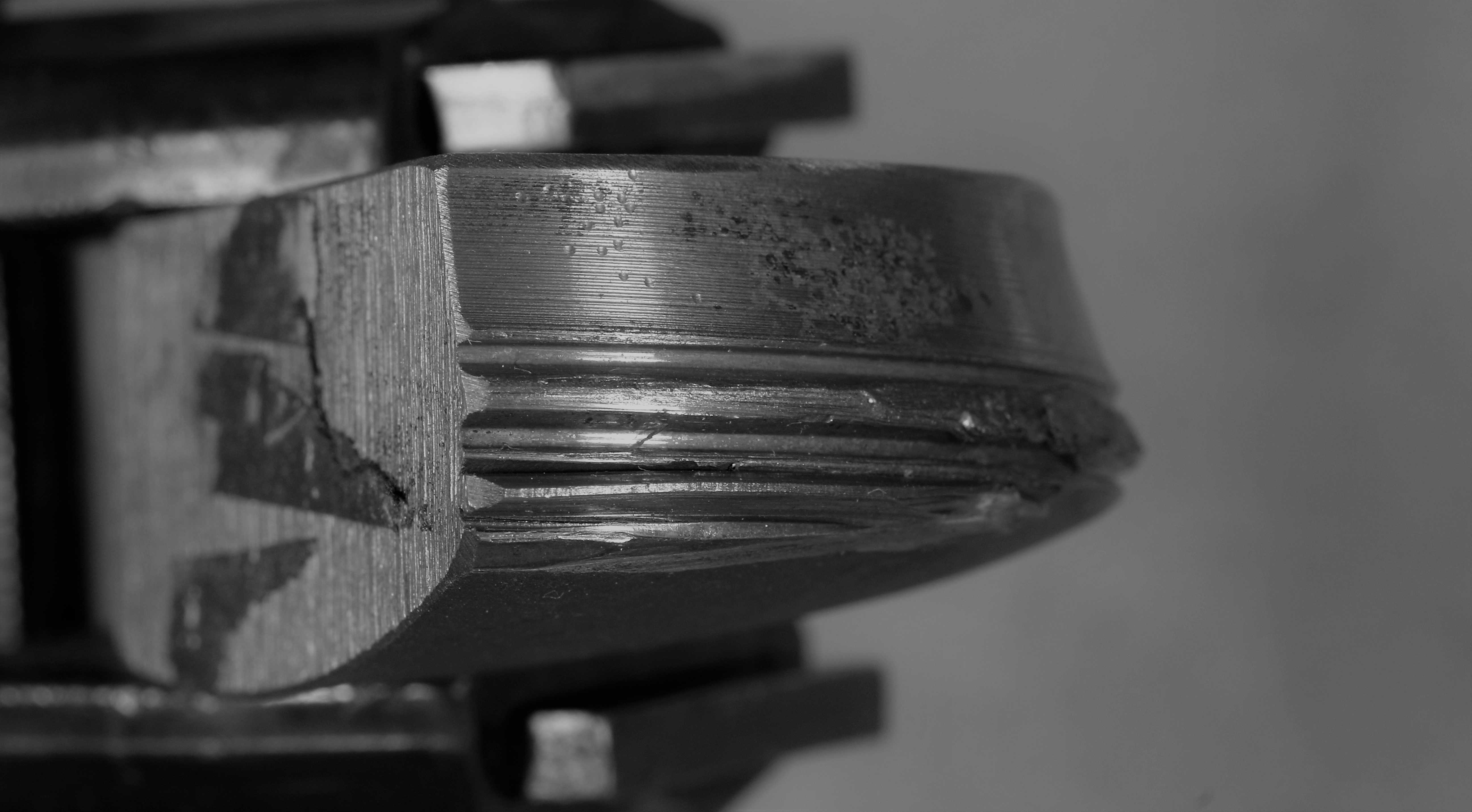

The actual cause of damage is often hidden in microscopic dimensions. The morphology and characteristics of a defect at high magnifications often already provide the necessary indications for identifying the cause, such as inclusions, hydrogen embrittlement or stress corrosion cracking. If supplementary or further investigations are necessary, we also have the appropriate material testing methods for this purpose.

Does your production require continuous, independent monitoring for quality assurance? We can offer you a solution customized to your needs. Modern spectroscopic and analytical methods are available. If you wish, we can also monitor your production around the clock, take samples at your site and transmit the results to you online within a very short time.

By selectively examining the chemical composition, we can determine the purity of the surface and, for example, make statements about whether prohibited chemicals (e.g. chromium plating with Cr (VI) salts) have been used.

X-ray photoelectron (XPS, ESCA) and Auger electron spectroscopy

FT-IR and UV-Vis spectroscopy

Light microscopy and scanning electron microscopy (SEM)